Year of Implementation: 2025

BEDNAR FMT

Industry: Agricultural Technology & Machinery

Country: Czech Republic

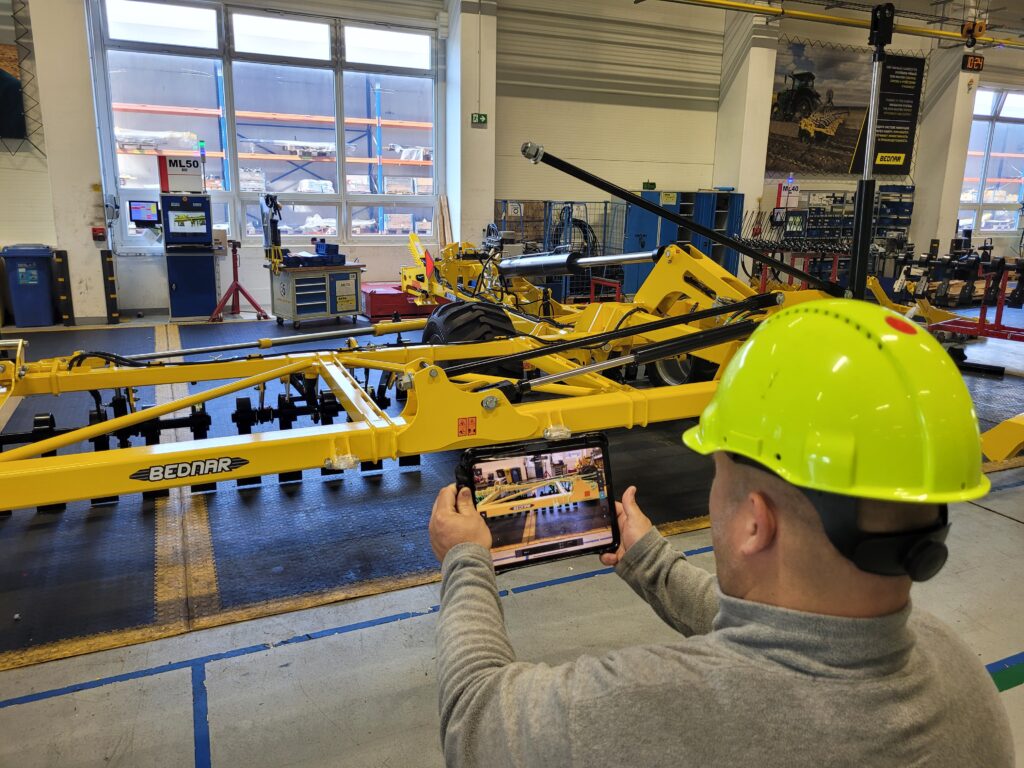

BEDNAR FMT: Digital Quality Control Using a 3D Model on a Tablet

BEDNAR FMT is a Czech manufacturer of high-end agricultural machinery with a global presence, delivering highly specialized machines and equipment that demand maximum precision and processing quality. To maintain the highest standards of quality, the company sought an innovative solution for quality control within its supply chain and production process.

Challenge

Traditional quality control was time-consuming and prone to human error, leading to production delays and increased costs. There was also a need to quickly detect defects before receiving parts from subcontractors, while ensuring easy access to quality control data for all relevant personnel.

Solution

To streamline and improve the accuracy of the inspection process, we jointly implemented a digital quality control system based on interactive 3D models displayed on tablets directly on the shop floor. This system enables:

- Accurate visualization of individual parts and components directly in the 3D model, enabling quick detection of deviations and defects.

- Intuitive operation and easy quality verification without the need for paper checklists, simplifying the workflow and speeding up the process.

- Instant access to inspection history, reports, and results in real time, improving transparency and quality traceability.

- Automatic documentation of all inspection steps, minimizing human error and ensuring consistent quality.

The customer actively uses the system for targeted incoming material inspections, ensuring the required quality from the very start of the production process. Inspections are also carried out at subcontractors’ sites, particularly for key components, helping to ensure smooth assembly without unnecessary interruptions caused by defective parts.

Key Benefits for BEDNAR FMT

- Reduced assembly downtime through early detection of defective parts.

- Lower inspection and repair costs thanks to process automation.

- Elimination of human error through a clear and fully digital quality control system.

- Fast and easy access to data, which can be easily shared and analyzed across the team.

- Early detection of faulty parts at suppliers significantly reduces transport costs and minimizes assembly delays.

- Immediate identification of defective units ensures a quick return on investment in the solution.

Conclusion

The implementation of quality control using a 3D model on a tablet has significantly improved the efficiency of incoming inspection, sampling, and supplier audits. The digitalization of inspection processes and enhanced detail visualization help eliminate errors, reduce costs, and greatly simplify the work of quality control personnel. This project is an excellent example of a successful digital transformation in the agricultural technology industry.

“Thanks to our cooperation with AYES, we were able to implement a 3D model-based digital quality control system, which enables us to detect defects faster before assembly.”

Vojtěch Bednář

Director of Production Management

BEDNAR FMT

“Before starting our cooperation, BEDNAR FMT tested several different quality control tools. We greatly appreciate that they ultimately chose our solution and established a long-term partnership with us.”

Jiří Soldát

Sales Consultant

AYES