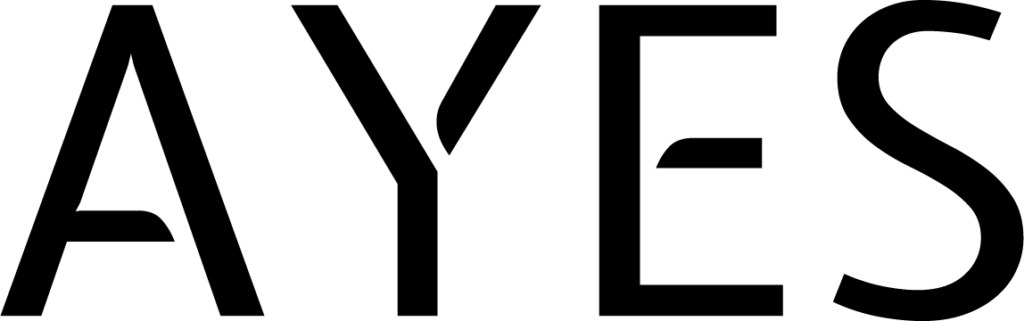

Work with 3D models created in CAD programs in augmented and vitual reality

3D Data Visualization

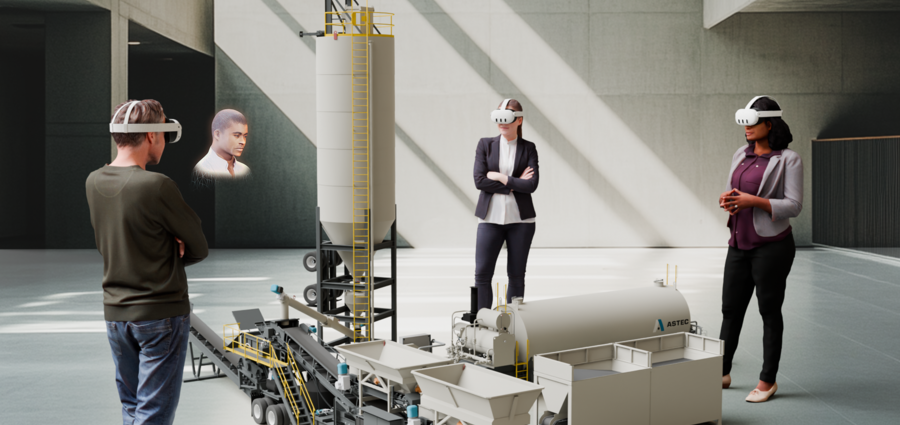

Place 3D objects into the real world, grab them, and move them naturally. Whether it’s product design, project engineering, production audits, machine ergonomics and safety checks, detection of design flaws, production planning, prototyping, or employee training, smart glasses with augmented and virtual reality provide an effective solution.

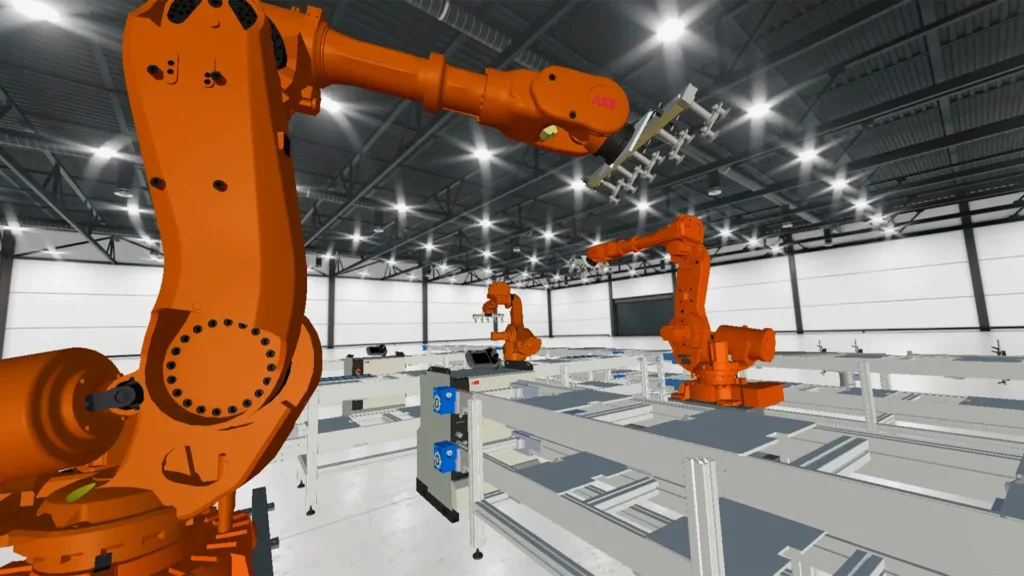

Factory Planning & Plant Design

Smart glasses can be used for planning and designing, such as new production lines or final project inspections. They enable the visualization of factories and complex assemblies in augmented and virtual reality, both on-site and before construction. This helps optimize workflows, machine placement, and safety measures, reducing design errors and saving time and costs by eliminating physical reconfigurations. Simply upload the proposed solution, such as a specific machine, in a 1:1 scale to the glasses and project it directly into the real environment.

Design Review & Product Presentation

Use AR/VR for full-scale 3D design reviews and immersive product presentations. Visualize machinery, vehicle parts, and complex products before physical production, reducing costs, waste, and development time. Interactive presentations enhance stakeholder engagement by showcasing products in realistic environments, improving communication and accelerating decision-making.

Main features and benefits

Benefits of use

reduction in errors

Quick and Easy Error Detection. Improves product quality by testing full-scale designs in a real-world environment.

faster concept design phase

Ensure faster time-to-market by accelerating product development with more effective design reviews and fewer iterations.

lower procduction costs

Economical & Sustainable Prorotyping. Saves money, reduces physical waste, and saves time by testing virtual prototypes.

3D CAD model visualization

Augmented reality enabled seamless customer and stakeholder engagement in the new build project. With the ability to visualize 1:1 3D CAD models in a realistic environment, the customer got a perfect idea of the final state.