Year of implementation:2023

Wistron

Industry: Technology company

Country: Czech Repuclic

Key benefits:

Innovative smart glasses technology revolutionises vision picking and logistics

Companies are constantly looking for ways to optimize their processes and increase efficiency. In the age of digitalisation, the innovative RealWear smart glasses technology has become a key element that is changing the way logistics operations are carried out. We had the opportunity to work with a manufacturer of high-end servers and data racks on this implementation.

This global company, with more than 20 years of history and offices around the world, found a helping hand in our solution that allowed employees to replace heavy and uncomfortable mobile terminals with RealWear Navigator™ 500 smart glasses. This decision greatly improved the handling and speed of order picking.

In order to facilitate the work and handling during barcode scanning, we have implemented wrist sensors from ProGlove, with which we actively cooperate on several projects. By combining technologies, we have increased work efficiency and freed up both hands to work without restrictions.

Easier handling without restrictions

The company gradually decided to replace traditional technologies with new, modern options. The reason was clear, to allow pickers (warehouse workers) to work without any restrictions, to free both hands for work and to create suitable working conditions.

The first step to success is a careful process analysis, where we presented a variety of hardware and software options from our portfolio. We then debugged the technology for field testing. The technology validation included Proof of Concept (PoC) testing in live operation using real order data from the current WMS. This data was accessible via a web interface. Company management and pickers were able to test the smart glasses and verify their benefits. Throughout the PoC, we at AYES provided full support and active collaboration with the pickers in testing different variants of the smart glasses. We responded to their needs and successfully resolved any issues in collaboration with the company’s development team.

Next, we performed a financial analysis that included the investment. Together with the process analysis, we also provided the return on investment for this new technology. In doing so, we proved that picking orders using smart glasses is indeed beneficial.

Solutions for vision picking in logistics processes

To meet all the requirements, we have introduced an innovative solution in the form of RealWear smart glasses, which are paired with a wrist scanner from ProGlove for barcode scanning. This solution did not require any complex integration or costly modifications to the existing WMS system they were currently using on the mobile terminals.

The display of the glasses allows operators to have the necessary information about product picking directly in their field of vision. This eliminates the need to carry a heavy mobile terminal throughout the shift. The controls are intuitive, user-friendly and individual transactions are controlled by voice instructions in English using a selection of numbers.

In addition, the wrist sensors, along with the RealWear Navigator 500 smart glasses, allow both hands to be free to work while simultaneously scanning 1D/2D barcodes, which has contributed to a faster and more convenient picking process.

How have smart glasses changed the work of pickers (step by step)?

The picker simply puts the smart glasses on his head at the start of his shift. It automatically launches an application that replicates the WMS view directly from the web interface. The picker then pairs the ProGlove wrist sensor with the smart glasses via a printed QR code.

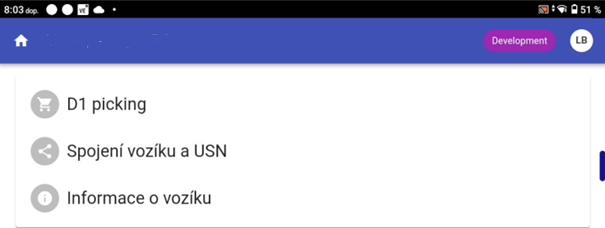

After successful login, the glasses display shows three available transactions that can be controlled by voice prompts. The picker speaks the given numbers “1-3” depending on what transaction needs to be performed. If he chooses incorrectly, the “menu” command is retained to return to the home screen.

This user interface is easy to understand and also makes it easy to train new employees.

Home screen (1-3)

Achieving a breakthrough with smart glasses

The implementation of RealWear smart glasses with the integrated ProGlove sensor into the company’s multipicking process has been successful and has resulted in significant efficiency gains, reduced errors, increased operator concentration and eliminated end device breakage. In addition, the vision picking solution made it easy to train new pickers regardless of language barrier as the entire system is very intuitive. The production manager adds: “The operators working with the technology themselves are very happy with the introduction of the smart glasses and the overall change. They had to carry the mobile terminals in their hands all the time, which limited their handling. Thanks to the sensor and the ergonomic design of the glasses, they no longer face such problems.“

The return on investment lies in the faster picking process, which now takes 9 minutes less per trolley compared to the original mobile terminal solution. This represents a significant increase in efficiency, especially given that 21 trolleys with 64 items are picked each day. It is also important to point out that there has been an elimination of dropped picked items during the process and a reduction in the number of broken terminals (mobile terminals), this has contributed to the overall return on investment with efficiency increasing by up to 30% and eliminating the breakage of terminals to zero.

Vision and plans

Our cooperation is just beginning! The innovative method of vision picking has proven so successful that we plan to extend this solution to other logistics processes

“A big thank you goes to the project manager for leading the whole project and to the production manager for his trust in the implementation of the technology and cooperation in fine-tuning the process to perfection,” says Lukáš Chamrad, our business consultant in charge of the project,“ says our sales consultant Lukáš Chamrad, who is in charge of the project.

„The operators working with the technology themselves are very happy with the introduction of the smart glasses and the overall change. They had to carry the mobile terminals in their hands all the time, which limited their handling. Thanks to the sensor and the ergonomic design of the glasses, they no longer face such problems.”

Production Manager

“A big thank you goes to the project manager for leading the whole project and to the production manager for his trust in the implementation of the technology and cooperation in fine-tuning the process to perfection.”

Lukáš Chamrad

Sales Consultant

AYES